1. ഉൽപ്പന്നം കഴിഞ്ഞുview

The Master Lock S430 is a 4mm lockout hasp designed for industrial safety applications. It features a 5/32" (4mm) diameter shackle, making it suitable for smaller lockout points. The hasp is constructed with a steel shackle and a durable plastic body, capable of holding up to two safety padlocks. This device is an integral part of a lockout/tagout program, ensuring equipment remains de-energized during maintenance or service.

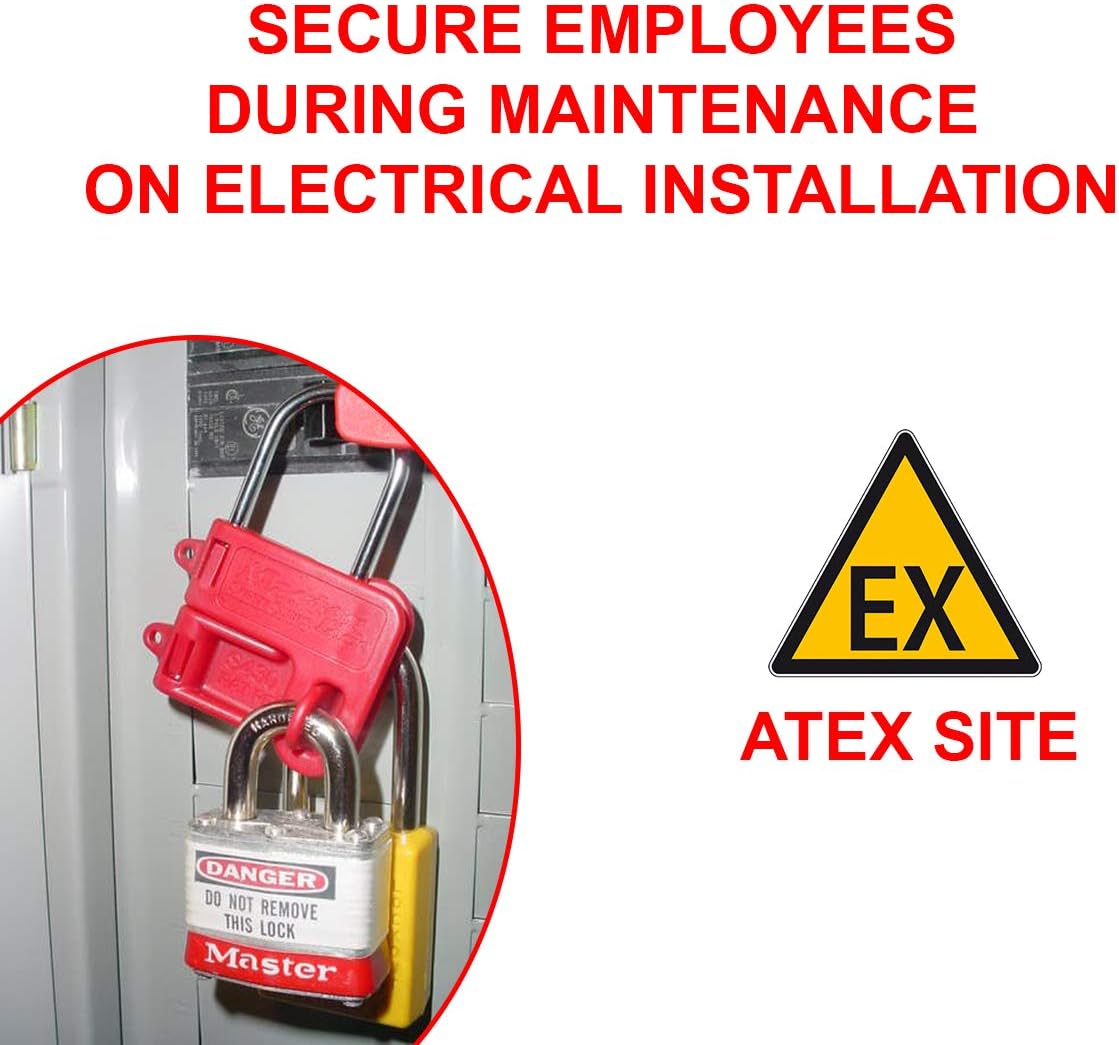

ചിത്രം 1.1: മുൻഭാഗം view of the Master Lock S430 4mm Lockout Hasp, showcasing its red plastic body and steel shackle.

2. സവിശേഷതകൾ

- കോംപാക്റ്റ് ഡിസൈൻ: 4mm (5/32") shackle diameter specifically designed to fit smaller lockout points.

- നീണ്ടുനിൽക്കുന്ന നിർമ്മാണം: Features a robust steel shackle for strength and a plastic body for lightweight durability.

- Multiple Lock Capacity: Designed to hold up to two safety padlocks, allowing multiple authorized employees to secure a single energy source.

- അനുയോജ്യത: Can be used in conjunction with the Master Lock S100 Lockout Leash Lanyard for added convenience and security.

- Inside Jaw Diameter: 2-1/4" x 3" x 1".

Image 2.1: Diagram highlighting the steel shackle, plastic body, and capacity to hold up to two safety padlocks on the S430 hasp.

3 സ്പെസിഫിക്കേഷനുകൾ

| ആട്രിബ്യൂട്ട് | വിശദാംശങ്ങൾ |

|---|---|

| മോഡൽ നമ്പർ | എസ് 430 |

| ബ്രാൻഡ് | മാസ്റ്റർ ലോക്ക് |

| ഷാക്കിൾ വ്യാസം | 4mm (5/32 inches) |

| മെറ്റീരിയൽ | Steel shackle, Plastic body |

| Body Dimensions (H x L x D) | 5.7 x 7.6 x 2 സെ.മീ (ഏകദേശം 2.24 x 3 x 0.79 ഇഞ്ച്) |

| ഇനത്തിൻ്റെ ഭാരം | 0.704 ഔൺസ് |

| നിറം | ചുവപ്പ് |

Image 3.1: Detailed diagram showing the shackle and body dimensions of the Master Lock S430 hasp.

4. Safety Information and Lockout/Tagഔട്ട് നടപടിക്രമം

The Master Lock S430 lockout hasp is designed to be used as part of a comprehensive Lockout/Tagout (LOTO) program to prevent unexpected startup of machinery or release of hazardous energy during maintenance or servicing activities. Adherence to established LOTO procedures is critical for personnel safety.

പൊതു സുരക്ഷാ മാർഗ്ഗനിർദ്ദേശങ്ങൾ:

- Always follow your facility's specific Lockout/Tagഔട്ട് നടപടിക്രമങ്ങൾ.

- Ensure all energy sources are identified and de-energized before applying lockout devices.

- Verify the isolation of energy by attempting to operate the equipment after lockout devices are applied.

- Each authorized employee involved in the service or maintenance should apply their own personal lockout device.

- Never attempt to remove another employee's lockout device.

Image 4.1: Illustration emphasizing the importance of a Lockout/Tagout program for employee safety, contrasting safe and unsafe practices.

ചിത്രം 4.2: ഉദാample of a lockout hasp securing an electrical installation, preventing accidental re-energization during maintenance.

5. ഉപയോഗ നിർദ്ദേശങ്ങൾ (പ്രവർത്തനം)

Follow these general steps for applying the Master Lock S430 lockout hasp as part of a standard Lockout/Tagout procedure. Always refer to your organization's specific LOTO policy.

- Preparation for Shutdown: Identify all energy sources and potential hazards associated with the equipment. Notify all affected personnel.

- Equipment Shutdown: Turn off or shut down the equipment using normal operating procedures.

- Isolation of System from Hazardous Energy: Disconnect or de-energize the equipment from its energy source(s). This may involve turning off circuit breakers, closing valves, or blocking moving parts.

- Application of Lockout/Tagout Devices:

- Place the Master Lock S430 hasp over the energy isolating device (e.g., circuit breaker handle, valve handle).

- Ensure the hasp fully encompasses the device, preventing its operation.

- Each authorized employee involved in the work should then attach their personal safety padlock through one of the holes on the hasp. The S430 can accommodate up to two padlocks.

- Attach a lockout tag to the hasp or padlock, providing information such as the name of the person who applied the lock, the date, and the reason for the lockout.

- Dissipation of Residual or Stored Energy: Safely release or restrain any stored energy (e.g., springs, hydraulic pressure, capacitors).

- Verification of Isolation: Attempt to operate the equipment to confirm that it cannot be started and that all energy sources are effectively isolated. Return controls to the "off" position after verification.

- Performing Service/Maintenance: Proceed with the necessary work.

- Removal of Lockout/Tagout Devices: Once work is complete and the equipment is safe to operate, remove lockout devices in reverse order of application, ensuring all personnel are clear.

Image 5.1: The Master Lock S430 hasp applied to a circuit breaker panel, secured with two safety padlocks, demonstrating its use in an electrical lockout scenario.

Image 5.2: A visual representation of the seven essential steps in a Lockout/Tagout procedure, from preparation to verification of isolation.

6. പരിപാലനം

The Master Lock S430 lockout hasp is designed for durability and requires minimal maintenance.

- പരിശോധന: Regularly inspect the hasp for any signs of damage, wear, or deformation. Check the steel shackle for bends or corrosion and the plastic body for cracks or breaks.

- വൃത്തിയാക്കൽ: Clean the hasp with a mild soap and water solution if it becomes dirty. Avoid harsh chemicals that could degrade the plastic material.

- സംഭരണം: Store the hasp in a clean, dry environment away from direct sunlight and extreme temperatures when not in use.

- മാറ്റിസ്ഥാപിക്കൽ: If any damage is observed that could compromise the integrity or function of the hasp, replace it immediately to ensure continued safety.

7. പ്രശ്നപരിഹാരം

The Master Lock S430 lockout hasp is a simple mechanical device. Most issues relate to improper application or damage.

- Hasp does not fit the lockout point:

- Ensure the lockout point's dimensions are compatible with the S430's 4mm shackle diameter and jaw dimensions.

- If the lockout point is too large, a different size hasp or lockout device may be required.

- Padlock does not fit through the hasp:

- Verify that the padlock shackle diameter is compatible with the holes on the S430 hasp.

- Use Master Lock safety padlocks designed for lockout/tagout applications, which are typically compatible.

- Hasp appears damaged or compromised:

- Do not use a damaged hasp. Immediately remove it from service and replace it with a new, undamaged unit.

- Damage can compromise the security and effectiveness of the lockout.

8. വാറൻ്റിയും പിന്തുണയും

For information regarding product warranty, technical support, or to inquire about other Master Lock safety products, please visit the official Master Lock webസൈറ്റ് അല്ലെങ്കിൽ അവരുടെ ഉപഭോക്തൃ സേവന വിഭാഗവുമായി ബന്ധപ്പെടുക.

മാസ്റ്റർ ലോക്ക് കമ്പനി LLC

www.masterlock.com