1. സജ്ജീകരണ ഗൈഡ്

The FLSUN V400 3D Printer is designed for quick and easy setup, arriving largely pre-assembled from the factory. Follow these steps to get your printer ready for its first print.

1.1 അൺബോക്സിംഗും പ്രാരംഭ പ്ലേസ്മെന്റും

Carefully remove all components from the packaging. Place the printer on a stable, level surface with adequate space around it for operation and maintenance. Ensure the power switch is in the OFF position before connecting to a power source.

Figure 1: The FLSUN V400 3D Printer, showcasing its delta design and large build volume.

1.2 Power Connection and Klipper Firmware

Connect the power cable to the printer and then to a wall outlet. The FLSUN V400 comes with Klipper firmware pre-installed on its dedicated pad, eliminating the need for complex firmware setup. The 7-inch wide-angle IPS display provides an intuitive interface for control.

Figure 2: The Speeder Pad with its pre-installed Klipper firmware, offering comprehensive control and monitoring.

1.3 PEI Bed Preparation and Filament Loading

Ensure the steel spring PEI sheet bed is securely placed on the print platform. For optimal adhesion, clean the PEI surface with 70% isopropyl alcohol before each print. Load your chosen filament into the direct drive extruder. The V400's direct drive system is designed for reliable feeding of various filament types.

1.4 Automatic Leveling System

The FLSUN V400 features an upgraded automatic leveling system with 25-point precise calibration. Initiate the auto-leveling process through the Speeder Pad interface. This ensures a perfectly level print surface for consistent first layers.

1.5 സജ്ജീകരണം കഴിഞ്ഞുview വീഡിയോ

വീഡിയോ 1: ഒരു ഉദ്യോഗസ്ഥൻview of the FLSUN V400 3D Printer, demonstrating its features and ease of use.

2. പ്രവർത്തന നിർദ്ദേശങ്ങൾ

The FLSUN V400 is engineered for high-speed, high-quality 3D printing. This section covers the basic operation and capabilities of your printer.

2.1 ഒരു പ്രിന്റ് ആരംഭിക്കുന്നു

After completing the setup and auto-leveling, select your desired print file from the Speeder Pad. The Klipper firmware allows for seamless operation and monitoring. The V400's advanced dual-axis linear guide ensures precise and stable movement during printing, contributing to superior print accuracy.

Figure 3: The FLSUN V400 integrated into a workspace, ready for creative projects.

2.2 High-Speed Printing Capabilities

The FLSUN V400 is capable of reaching impressive printing speeds of up to 600mm/s with an acceleration of 25000+ mm/s². This significantly reduces print times compared to conventional 3D printers.

Figure 4: A visual comparison highlighting the FLSUN V400's superior printing speed.

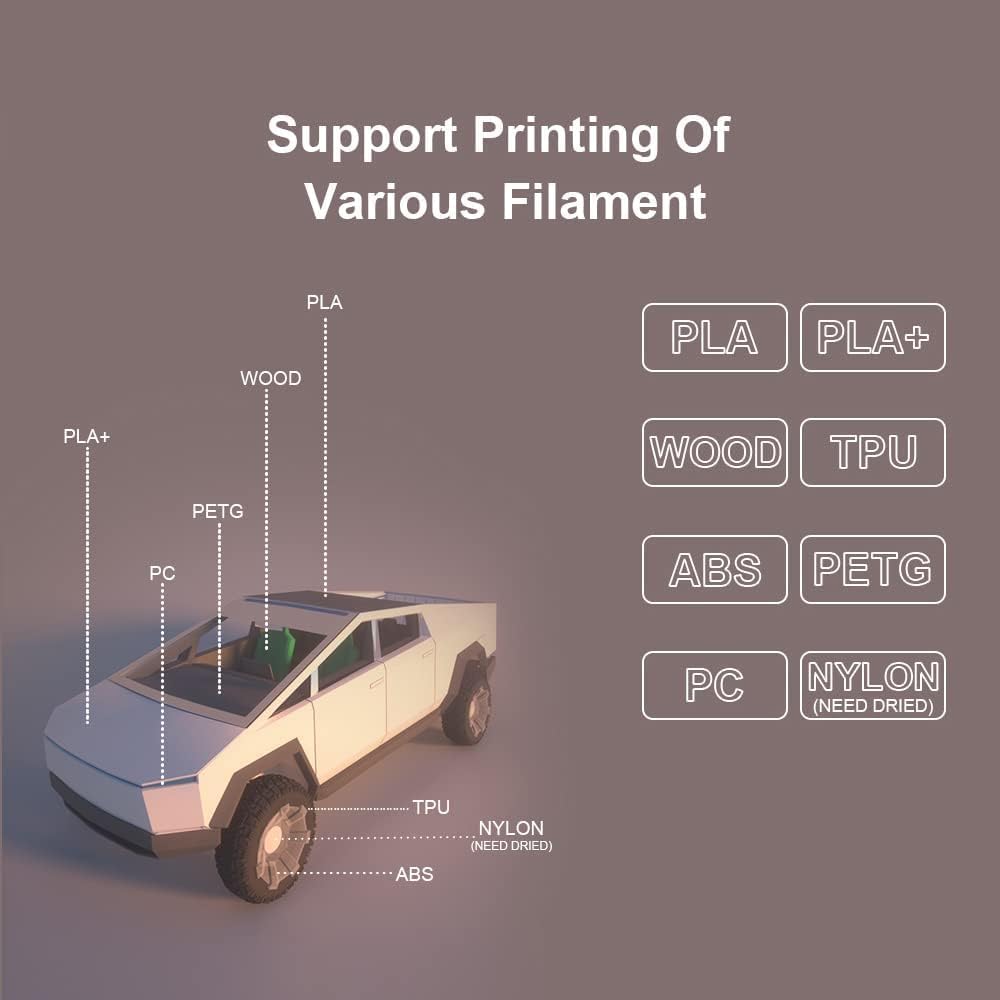

2.3 Filament Compatibility and Nozzle Temperature

The bi-metal 300℃ high-temp nozzle and direct drive extruder allow the V400 to print with a wide range of filaments, including PLA, PLA+, WOOD, TPU, ABS, PETG, PC, and NYLON. For NYLON filament, ensure it is properly dried before use to prevent printing issues.

Figure 5: The FLSUN V400 supports a diverse range of filament materials for various applications.

2.4 Direct Drive Extruder

The FLSUN V400 is equipped with an all-metal direct drive extruder capable of 70N force and weighing just 135g. This lightweight and powerful extruder supports high-speed printing requirements and provides excellent control over filament feeding.

Figure 6: The FLSUN V400's direct drive extruder, designed for precision and high performance.

2.5 വലിയ പ്രിന്റിംഗ് വോളിയം

The FLSUN V400 offers a generous printing volume of Φ300mm (Diameter) x 410mm (Height), providing ample space for larger models and batch printing.

Figure 7: The impressive printing size of the FLSUN V400, ideal for larger projects.

3. പരിപാലനം

Regular maintenance ensures the longevity and optimal performance of your FLSUN V400 3D Printer.

3.1 പ്രിന്റ് ബെഡ് ക്ലീനിംഗ്

After each print, allow the PEI sheet bed to cool down. Once cool, models can be easily removed by flexing the steel spring sheet. Clean the surface with 70% isopropyl alcohol to remove any residue and ensure strong adhesion for subsequent prints.

3.2 Nozzle and Extruder Care

Periodically inspect the bi-metal 300℃ high-temp nozzle for any clogs or wear. If necessary, perform a cold pull or use a nozzle cleaning needle to clear obstructions. Ensure the direct drive extruder gears are free from filament debris.

3.3 Linear Guide Lubrication

The dual-axis linear guide system benefits from occasional lubrication to maintain smooth operation and minimize noise. Refer to the detailed maintenance guide for recommended lubricants and application frequency.

3.4 Filament Storage

Store filaments, especially hygroscopic materials like NYLON, in a dry environment. Using a filament dryer for such materials before printing is highly recommended to achieve the best print quality and prevent issues like stringing or poor layer adhesion.

4. പ്രശ്നപരിഹാരം

This section addresses common issues you might encounter during the operation of your FLSUN V400 3D Printer.

4.1 Poor First Layer Adhesion

- പ്രിന്റ് ബെഡ് വൃത്തിയാക്കുക: Ensure the PEI sheet is thoroughly cleaned with isopropyl alcohol before each print.

- Re-run Auto-Leveling: If issues persist, perform the 25-point automatic leveling calibration again to ensure proper bed height.

- Adjust Z-Offset: Fine-tune the Z-offset during the first layer of a print to achieve optimal squish.

4.2 Clogging or Under-extrusion

- Check Nozzle: Inspect the nozzle for blockages. A cold pull or cleaning needle can often resolve this.

- Filament Quality/Drying: Ensure your filament is dry, especially for hygroscopic materials. Wet filament can cause steam and bubbles, leading to poor extrusion.

- Extruder Gears: Verify that the direct drive extruder gears are not clogged with filament dust and are gripping the filament properly.

4.3 Print Quality Issues (Layer Shifting, Poor Surface Finish)

- Check Belts/Rods: Ensure the carbon fiber rods and linear guides are clean and moving freely.

- പ്രിൻ്റ് വേഗത: While the V400 is fast, ensure your print speed is appropriate for the filament and model complexity.

- തണുപ്പിക്കൽ: Verify that the fast cooling fan is operating effectively, especially for PLA.

5 സ്പെസിഫിക്കേഷനുകൾ

| ഫീച്ചർ | വിശദാംശങ്ങൾ |

|---|---|

| മോഡൽ | V400 |

| ബ്രാൻഡ് | FLSUN |

| പ്രിന്റിംഗ് വേഗത (പരമാവധി) | 600mm/s |

| ത്വരണം (പരമാവധി) | 25000+ മിമി/സെ² |

| Printing Size (Diameter x Height) | Φ300mm x 410mm (Φ11.8" x 16") |

| എക്സ്ട്രൂഡർ തരം | All-metal Direct Drive |

| Nozzle Temperature (Max) | 300℃ |

| ഫേംവെയർ | Pre-installed Klipper |

| പ്രദർശിപ്പിക്കുക | 7-inch wide-angle IPS |

| ലെവലിംഗ് സിസ്റ്റം | 25-point Automatic Leveling |

| പ്രിന്റ് ബെഡ് | Steel Spring PEI Sheet |

| ഇനത്തിൻ്റെ ഭാരം | 40 പൗണ്ട് |

| ഉൽപ്പന്ന അളവുകൾ | 98.8 x 48.8 x 20.8 ഇഞ്ച് |

6. വാറൻ്റിയും പിന്തുണയും

FLSUN is committed to providing excellent customer service for your 3D printer. For any issues or inquiries regarding your FLSUN V400, please do not hesitate to reach out to our dedicated customer support team.

We strive to provide prompt assistance within 24 hours to ensure your printing experience is smooth and enjoyable.

For the most up-to-date warranty information and support resources, please visit the official FLSUN website or contact our support channels directly.